Adhesive surface preparation

Efficiency, sustainability and quality in surface pretreatment

Adhesive surface preparation

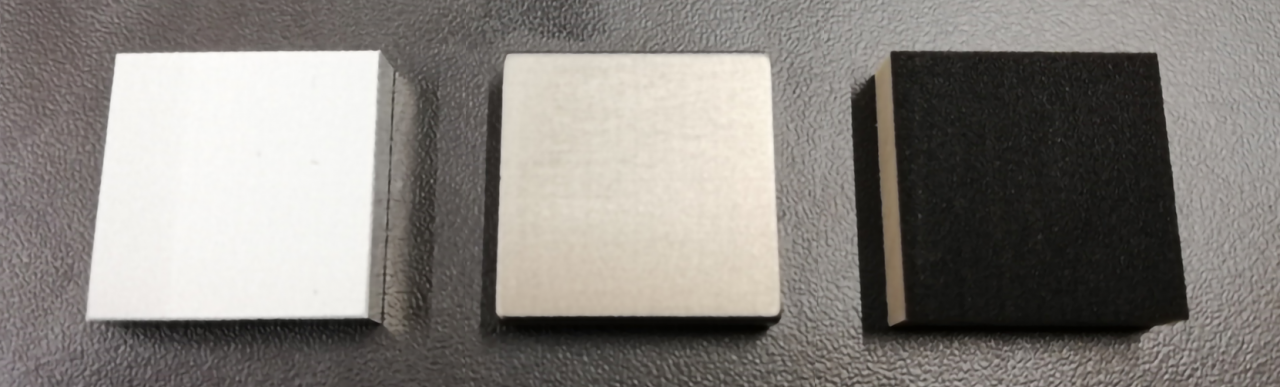

Laser processing to prepare surfaces before bonding offers enormous advantages. This ensures that the bond is of high strength and correspondingly durable.

Industrial joining technology is no longer conceivable without reliable adhesive bonds. Particularly in sectors such as the automotive industry, aerospace and mechanical engineering, optimum preparation of the bonding surfaces plays a decisive role in the quality and durability of the bond. In this context, laser cleaning offers a modern, environmentally friendly and extremely precise alternative to conventional cleaning processes such as sandblasting, grinding or chemical pickling.

Basics of laser cleaning

Laser cleaning (also known as laser ablation) uses short, high-energy laser pulses to selectively remove unwanted layers - such as oxides, grease, dust, paint or corrosion - from the surface without damaging the base material. The process is based on physical principles:

- Ablation by thermal energy: Impurities absorb the energy of the laser beam, vaporise or decompose.

- Pulsed laser: Short pulses prevent excessive thermal stress on the substrate.

- No mechanical stress: In contrast to abrasive processes, the surface remains structurally intact.

Advantages of laser cleaning for adhesive surfaces

| Advantage | Description of the |

|---|---|

| Residue-free cleaning | Removal of oil, grease, oxide, paint and much more - without the use of chemicals |

| Microscopically precise machining | Ideal for geometrically complex workpieces and selective cleaning |

| Improved adhesion | Increase in surface energy → better wettability through adhesives |

| Can be automated | Easy integration into existing production lines and robot solutions |

| Environmentally friendly | No use of solvents, no abrasive waste |

| Cost reduction | Less consumables required, shorter set-up times, reduced reworking |

Process parameters and material compatibility

The effectiveness of laser cleaning depends largely on the parameters used:

- Laser power (watts)

- Pulse duration (ns - fs)

- Wavelength (typically 1064 nm, Nd:YAG or fibre laser)

- Scan speed and line spacing

- Material type and degree of contamination

Suitable materials:

- Metals (e.g. aluminium, steel, titanium)

- Plastics (with restrictions - test required)

- Composite materials (carbon, GFRP, CFRP)

Application scenarios

- Automotive industry

- Preparation of car body components before bonding

- Cleaning of aluminium die-cast parts before seal application

- Aerospace industry

- Cleaning of CFRP components for structural bonding

- Removal of release agents and oxide layers

- General industry

- Replacement of chemical cleaning in series production

Quality assurance and auditability

Laser cleaning can be validated using various methods:

- Contact angle measurement (wettability)

- XPS / Auger analysis (surface chemistry)

- Microscopy (impurities / surface structure)

- Destructive tests (e.g. tensile tests of bonded samples)

Consistent cleaning quality can be guaranteed through the use of inline monitoring systems, e.g. plasma lights or camera monitoring.

Economic consideration

The initial investment in laser systems can be quickly amortised through savings on consumables, disposal costs and reduced rework. Process stability and traceability also increase production reliability - an increasingly important factor in certified industries.

Conclusion

Laser cleaning is a future-orientated technology for preparing adhesive surfaces. It combines maximum precision with environmental friendliness and offers high automation potential. Companies that rely on durable, reproducible bonded joints benefit considerably in terms of both quality and cost-effectiveness.

Suitable products

Smoke extraction systems

Reliably extract and filter laser smoke, laser particles and fumes

VisionSystem Check and Confirm

Checking data matrix codes, barcodes, QR codes by reading against them

Signal light

Reliable signalling for maximum visibility and safety

PenSoft Connect IP

Software für die Typenschildproduktion

Schwenkarm

Komfort und Funktionalität in perfekter Harmonie

Hand scanner

Powerful, flexible and reliable

Foot switch

Foot switch for Penteq laser machines

OEM fibreline high power

Ready-to-install laser for numerous applications

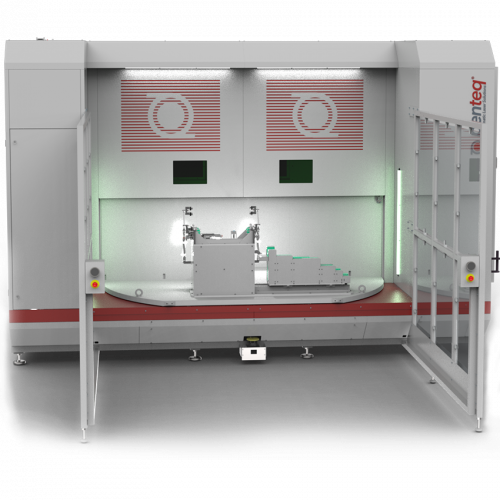

Turntable Laser system with robot

Turntable system with manipulation and laser robot