Paint stripping

Removing layers of paint without chemicals or abrasives: Laser paint stripping offers maximum precision with minimum use of materials.

Laser paint stripping

Removing layers of paint without chemicals or abrasives: Laser paint stripping offers maximum precision with minimum use of materials.

Whether for the paint stripping of metal parts, the selective cleaning of components or the preparation for post-processing - the process is versatile, efficient and ideal for automated production processes.

What is laser paint stripping?

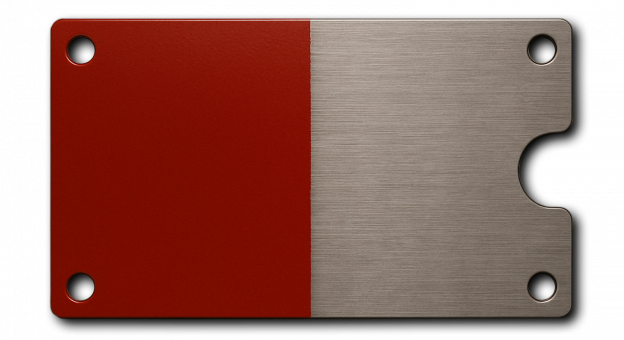

In laser paint stripping, paint, colour or coating is removed from the surface using highly focused laser beams - without damaging the base material. The energy of the laser dissolves the coating thermally or by ablation, turning it into particles or vapour.

Typical applications range from localised paint removal to the complete paint stripping of complex components. The stripping of cathodic dip painting (CDP) coatings using laser technology offers a highly precise and economical alternative to conventional paint stripping processes such as blasting or chemical stripping.

Advantages of laser paint stripping at a glance

- Non-contact process - no mechanical stress

- Precise & selective cleaning - ideal for sensitive or structured surfaces

- No chemicals - environmentally friendly and safe for employees

- No abrasive residues - clean processes, less reworking

- Can be automated - ideal for series production and inline integration

- Low operating costs - no consumables such as abrasives or solvents

Typical areas of application

- Removal of powder coating, paint or primer on aluminium, steel, stainless steel, galvanisedmetals, composite materials(partially, depending on absorption)

- Paint stripping for repair and restoration

- Preparation for welding, bonding or measuring processes

- Exposure of contact surfaces in electrical engineering

Technology & process details

Our systems utilise depending on the application:

- Fibre laser (1064 nm) - powerful and universally applicable

- Short-pulse or ultrashort-pulse lasers - for fine, sensitive surfaces

- Scanner or gantry technology - adapted to geometry and cycle times

The power, pulse rate and focus diameter of our laser systems are precisely adapted to the material, paint quality and coating thickness - to achieve optimum cleaning quality without damaging the substrate.

A particularly demanding area of application for laser paint stripping is the preparation of contact surfaces for electrical connections. In many industrial applications - for example in automotive engineering, power electronics or mechanical and plant engineering - certain areas of a component must be free of the cathodic dip coating to ensure reliable electrical conductivity. Cathodic dip-paint coatings have an insulating effect and prevent the safe flow of current or the formation of permanent contact connections, e.g. for earthing points, earthing rails or screw connections with a conductive function. With laser technology, these contact surfaces can be stripped with high precision, reproducibly and without damaging the base material. The laser specifically removes only the coating, while the underlying metal surface is cleanly exposed. This is crucial for the quality and long-term stability of the electrical connection. Thanks to the non-contact processing, even sensitive or complex geometries are easily achieved - without any masking or post-processing. The process parameters can be precisely customised to the respective material combination, which guarantees controlled and reliable exposure. In this way, laser-based paint stripping not only ensures optimum electrical contacts, but also makes a significant contribution to process reliability and quality in series production.

Comparison with conventional paint stripping processes

| Procedure | Laser paint stripping | Chemical | Sandblasting |

|---|---|---|---|

| Precision | ⭐⭐⭐⭐ | ⭐ | ⭐⭐ |

| Environmentally friendly | ⭐⭐⭐⭐ | ⭐ | ⭐⭐ |

| Can be automated | ⭐⭐⭐⭐ | ⭐ | ⭐⭐ |

| Gentle on materials | ⭐⭐⭐⭐ | ⭐⭐ | ⭐ |

| Effort / rework | Low | High | Medium |

Why rely on lasers?

Laser paint stripping not only saves time and money, but also meets strict environmental regulations and the requirements of modern, digitalised production lines.

A one-off investment in a laser system permanently reduces operating costs - without any chemicals, storage costs or disposal costs.

Get advice now - we'll find the right solution

Whether single part machining, series production or process development - we offer you:

- Test cleaning with your material

- Advice on system integration

- Delivery of turnkey laser systems

- Training & support

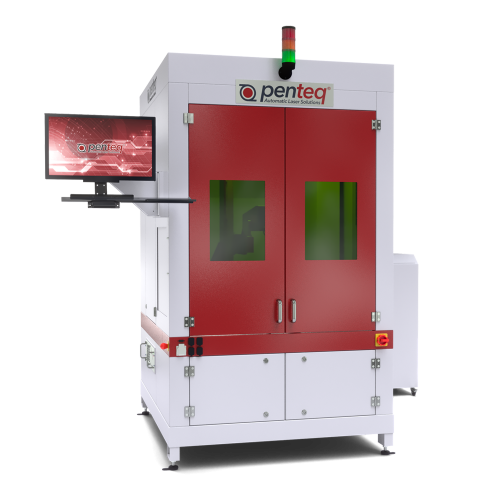

Suitable products

Laser workstation LG 200

Modularity as a pioneering concept

PenSoft Control

Easy-to-use interface for laser applications

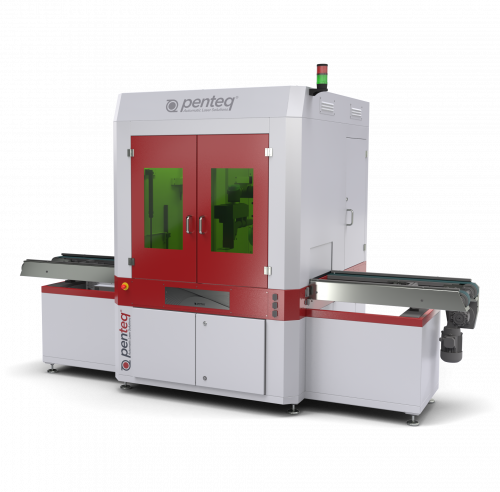

Laser system with conveyor belt

Automatic laser system with flexible workpiece carriers

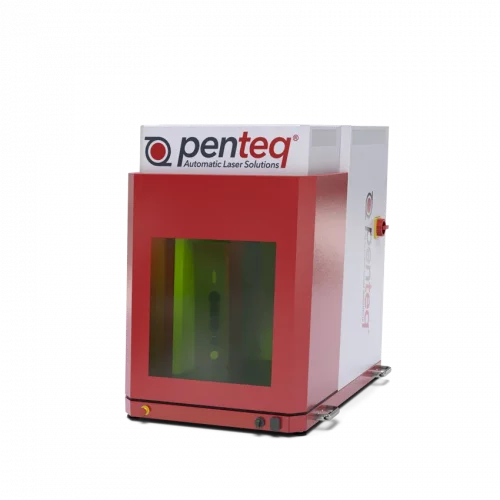

Desktop Laser LG100

Premium table system in industrial laser technology

Desktop Laser LG150

The all-rounder in industrial laser technology

Rotary table laser LG200 RT

For maximum production speed

LG200 with vibratory feeder

based on LG200 function module laser system for automatic labelling of bulk goods

Laser workstation LG300

Spacious work area and double pull-out table for maximum throughput rates

LG300 RT round table laser system

Maximum productivity in large format

Laser workstation LG 500

the top class for XL formats in laser processing

OEM fibreline

Ready-to-install laser for numerous applications

LG500 A Double shutter

Automatic loading system for large workpieces

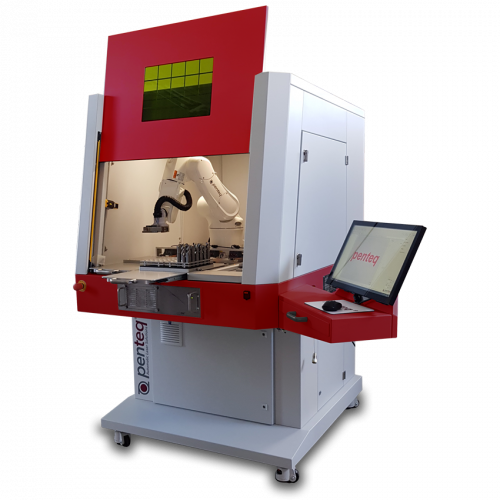

SG 500 RoboLaser

Flexibility through laser robots

LG200 RT with vibratory feeder

based on LG200 RT rotary table laser system for automatic labelling of bulk goods

Laser workstation LG 500 Robo

Fully automatic and flexible with integrated robot

Rotary transfer laser system

Automatic with flexible workpiece holders

Integration station

Laser system for easy integration into conveyors

VisionSystem Verifier

Verification of e.g: Data Matrix codes, barcodes, QR codes, etc.

Smoke extraction systems

Reliably extract and filter laser smoke, laser particles and fumes

VisionSystem Check and Confirm

Checking data matrix codes, barcodes, QR codes by reading against them

Further applications

Electromobility - Batteries

Penteq uses lasers to clean, weld and mark battery cells for electromobility in order to optimise battery performance and service life

Stripping

Stripping & stripping of copper wires for the electronics industry

Adhesive surface preparation

Efficiency, sustainability and quality in surface pretreatment

Rust removal

Efficient laser cleaning of corroded surfaces

Industries

Mechanical engineering

We use state-of-the-art laser technology to create precise, durable solutions for demanding plant and mechanical engineering applications

Tool+mould making

Our laser machines enable precise engraving and labelling in tool and mould making, which increases efficiency and adaptation to workpiece geometries

Electronics industry

Penteq laser machines offer precise cutting, welding and marking for the electrical industry, ideal for battery cells and electronic components

Automotive industry

Penteq laser machines enable precise cutting, welding and labelling in the automotive industry, especially for batteries and metal components

Air+Space

With innovative laser technology, Penteq delivers precise and reliable solutions for the highest demands in the aerospace industry

Maritime industry

Penteq supplies robust laser technology for precise material processing and labelling despite the harshest maritime environments