Cutting off plastic sprues

Laser cutting is an innovative, non-contact process for removing sprues from plastic parts directly after injection moulding.

Cutting off plastic sprues

Precise. Contactless. Efficient.

The sprue is the area of a plastic part through which the melt enters the mould during the injection moulding process. After solidification, this connecting web is separated. It can vary depending on the size and geometry of the moulded part and the injection process (spot, film or cold runner gate).

What is laser cutting of plastic sprues?

Laser cutting is an innovative, non-contact process for removing sprues from plastic parts directly after injection moulding. Using high-precision laser technology, the sprues are removed cleanly and in a material-saving manner - without mechanical stress on the workpiece.

Why laser technology instead of mechanical separation?

Conventional methods such as punching or cutting reach their limits with complex geometries or sensitive materials. Laser-based systems offer decisive advantages here:

- Non-contact: No tool wear, no mechanical deformation

- Maximum precision: Ideal for intricate structures and tight tolerances

- Clean cutting edges: Hardly any reworking necessary

- Can be automated: Can be integrated into existing production lines

Typical areas of application

Laser cutting is particularly suitable for:

- Medical technology - sterile processing without residues

- Automotive industry - high repeat accuracy for series production

- Electronic components - finest details without microcracks

- Consumer goods industry - clean surfaces without burrs

Automation & inline capability

A major advantage is that laser cutting can be easily integrated into automated production lines - inline directly after injection moulding or in separate post-processing cells.

- Robot-assisted feeding

- Cycle time-optimised processing

- Interfaces to MES/ERP systems

Comparison of sprue cutting processes

| Criterion | Laser cutting | Mechanical (knife/punch) | Thermal (hot cutter) | Manual (pliers, knife) |

|---|---|---|---|---|

| Non-contact | ✔️ Yes | ❌ No | ❌ No | ❌ No |

| Cutting quality | ⭐⭐⭐⭐ Very high | ⭐⭐ Medium | ⭐ Low | ⭐ Low |

| Burr formation | ❌ None or minimal | ✔️ Possible | ✔️ Clear | ✔️ Clear |

| Material deformation | ❌ None | ✔️ Possible (especially for thin parts) | ✔️ High (heat distortion) | ✔️ Possible |

| Repeatability | ⭐⭐⭐⭐ High | ⭐⭐ Medium | ⭐ Low | ❌ None |

| Automation capability | ✔️ Very good | ✔️ Possible, but limited | ❌ Difficult | ❌ Not possible |

| Cutting speed | ⭐⭐⭐ Fast | ⭐⭐⭐⭐ Very fast | ⭐⭐ Medium | ⭐ Slowly |

| Tool wear | ❌ None | ✔️ High (cutting, punching) | ✔️ High (heating elements) | ✔️ High |

| Costs per part (long-term) | ⭐⭐ Medium | ⭐⭐ Medium | ⭐ Low short-term, high long-term | Low for small series |

| Investment costs | 🡹 High (system, laser source) | 🡹 Means (tools + mechanics) | 🡻 Low | 🡻 Very low |

| Flexibility with geometries | ⭐⭐⭐⭐ Very high (also 3D) | ⭐⭐ Medium (depending on mould shape) | ⭐ Low | ⭐⭐ Medium |

| Post-processing necessary? | ❌ Mostly not | ✔️ Frequent | ✔️ Yes | ✔️ Yes |

| Suitable for series production | ✔️ Optimal | ✔️ Restricted | ❌ No | ❌ No |

Frequently asked questions (FAQ)

Which materials can be cut with a laser?

All common thermoplastics such as ABS, PC, PP, PE, POM and fibre-reinforced plastics.

How fast is the process?

Depending on component geometry and material: a few seconds per interface - ideal for short cycle times in mass production.

Is post-processing necessary?

Not in most cases. The edges are smooth and clean, without mechanical damage.

Our laser technology in detail

We use modern CO₂, fibre or UV lasers - depending on the requirements and the material to be separated. Our lasers can be optionally equipped with vision systems and offer:

- Camera-supported component recognition

- Automatic focussing

- Dynamic cutting according to component contour

- Integrated special laser fume extraction

Get advice now

Benefit from our experience in laser material processing. Our experts will support you in selecting the right technology for your application.

Suitable products

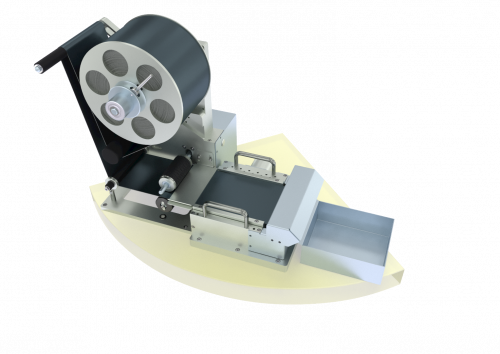

FM Labemaker

Label and cut permanent laser labels in any shape and size with the Labelmaker function module

FM focus finder

Easily detect the component height with the focus finder function module

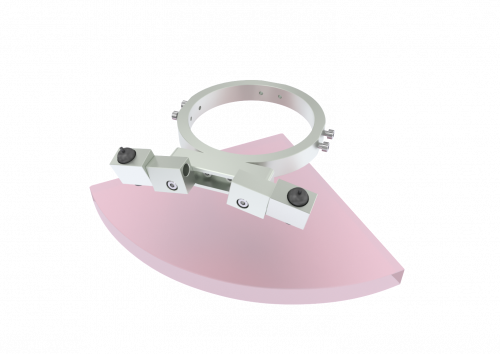

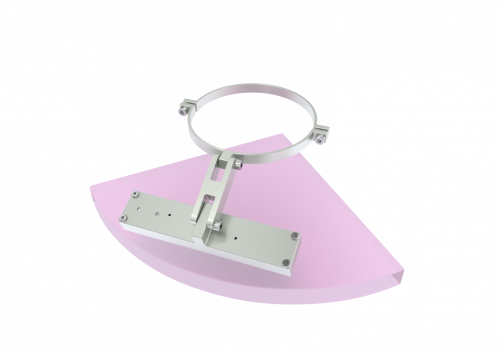

FM SmartAdjust (PSA)

Use the SmartAdjust function module to position the machining layout on the workpiece

VisionSystem Verifier

Verification of e.g: Data Matrix codes, barcodes, QR codes, etc.

Smoke extraction systems

Reliably extract and filter laser smoke, laser particles and fumes

VisionSystem Check and Confirm

Checking data matrix codes, barcodes, QR codes by reading against them

Signal light

Reliable signalling for maximum visibility and safety

PenSoft Connect IP

Software für die Typenschildproduktion

Schwenkarm

Komfort und Funktionalität in perfekter Harmonie

Hand scanner

Powerful, flexible and reliable

Foot switch

Foot switch for Penteq laser machines

OEM fibreline high power

Ready-to-install laser for numerous applications