OEM fibreline High Power

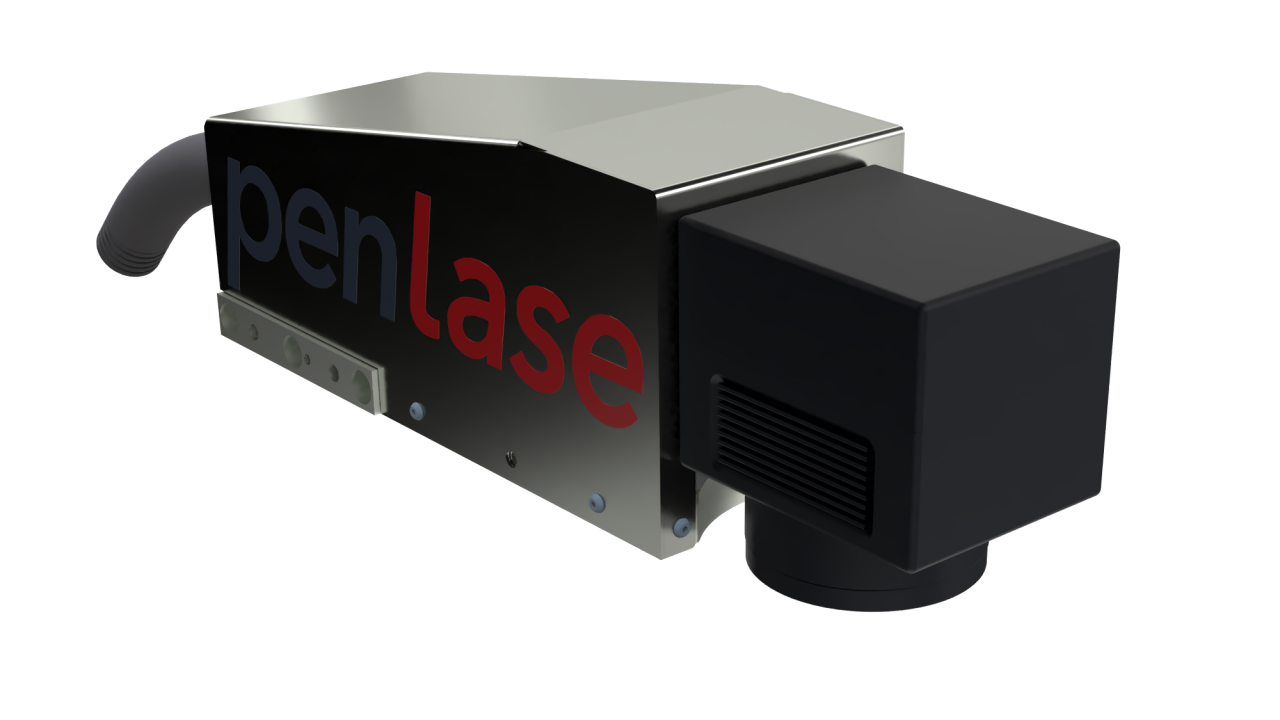

Ready-to-install laser for numerous applications

You can also visit the OEM Fiberline on our

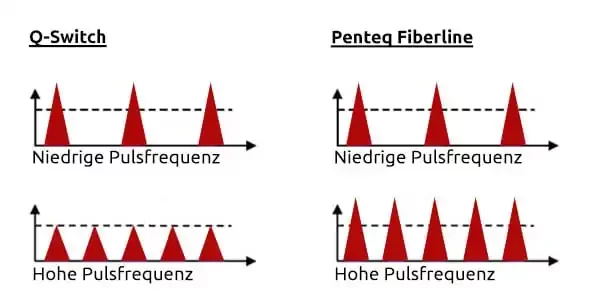

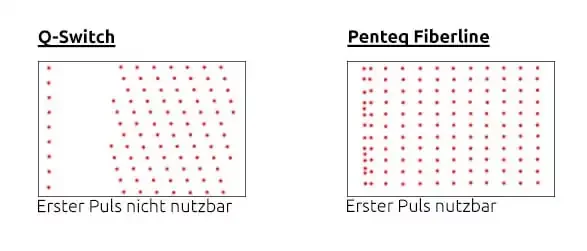

Fiberline: A technology with unique advantages

The OEM Fiberline series stands for precision and efficiency in industrial production. Compared to conventional Q-Switch lasers, the Fiberline offers full power from the very first pulse. Its flexible optical fibre connects the compact laser head to the supply unit, allowing even demanding production environments to be served.

Powerful beam source

The diode-pumped Fiberline is air-cooled, energy-saving and offers top performance at a wide range of frequencies - perfect for applications with high precision requirements.

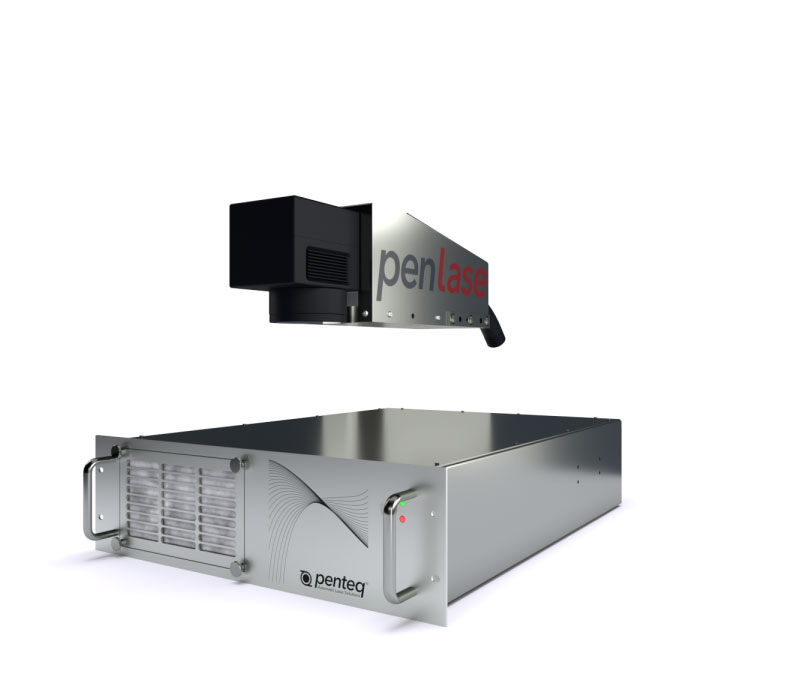

Modular and compact design

The supply unit in 19″ plug-in format makes integration into existing production systems simple and space-saving. The operating unit with screen, keyboard and mouse can be positioned anywhere, allowing it to be optimally positioned.

Simple integration and control

Optional interfaces such as Profinet or OPC-UA ensure the simplest connection and smooth communication. A remote maintenance option enables fast and reliable support.

Intuitive software

The user-friendly software allows intuitive operation without a long familiarisation period. Complete solutions with vision systems or the control of up to 6 axes directly from the Pensoft interface are optionally available.

OEM Fiberline - Your solution for precise laser processing

Rely on the innovative advantages of the OEM Fiberline. Contact us today and find out how this integration system can fulfil your production requirements efficiently and precisely.

| Output power | 20 watts |

| Standard field of work | 150 x 150 mm |

| Fields of work Optional | 50 x 50 to 300 x 300mm |

| Frequency | 20 - 400 kHz |

| Wavelength | 1064 nm + / - 8 nm |

| Working distance approx. | 245mm |

| Power consumption | 310 W |

| Weight approx. (head and supply unit) | 35 kg |

| Output power | 30 watts |

| Standard field of work | 150 x 150 mm |

| Fields of work Optional | 50 x 50 to 300 x 300 mm |

| Frequency | 30 - 400 kHz |

| Wavelength | 1064 nm +/- 8 nm |

| Working distance approx. | 245 mm |

| Power consumption | 420 W |

| Weight approx. (head and supply unit) | 40 kg |

| Output power | 50 watts |

| Standard field of work | 150 x 150 mm |

| Fields of work Optional | 50 x 50 - 300 x 300 mm |

| Frequency | 50 - 400 kHz |

| Wavelength | 1064 nm +/- 8 nm |

| Working distance approx. | 245 mm |

| Power consumption | 500 W |

| Weight approx. (head and supply unit) | 40 kg |

| Output power | 100 watts |

| Standard field of work | 150 x 150 mm |

| Fields of work Optional | 50 x 50 - 300 x 300 mm |

| Frequency | 50 - 400 kHz |

| Wavelength | 1064 nm + / - 4 nm |

| Working distance approx. | 245 mm |

| Power consumption | 850 W |

| Weight approx. (head and supply unit) | 45 kg |

| Output power | 120 watts |

| Standard field of work | 150 x 150 mm |

| Fields of work Optional | 50 x 50 - 300 x 300 mm |

| Frequency | 50 - 400kHz |

| Wavelength | 1064nm+ / -4nm |

| Working distance approx. | 245 mm |

| Power consumption | 850 W |

| Weight approx. (head and supply unit) | 45 kg |

| Positioning laser | to preview the layout on the workpiece as a projection |

| Control | Up to 6 axes from the Pensoft surface |

| 3D function | for curved, angled or free-form surfaces |

| PSA Smart Adjust | to preview the processing in the transparent layout |

| Vision systems | for checking codes or product properties |

| Touch Screen | Direct input via the screen |

| Supply line | Special lengths up to 12 m |

Matching products

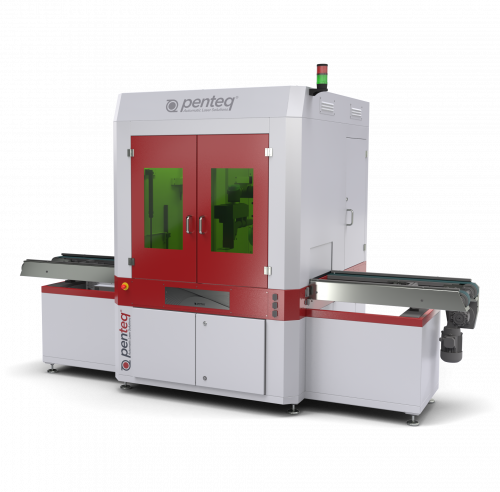

Rotary transfer laser system

Automatic with flexible workpiece holders

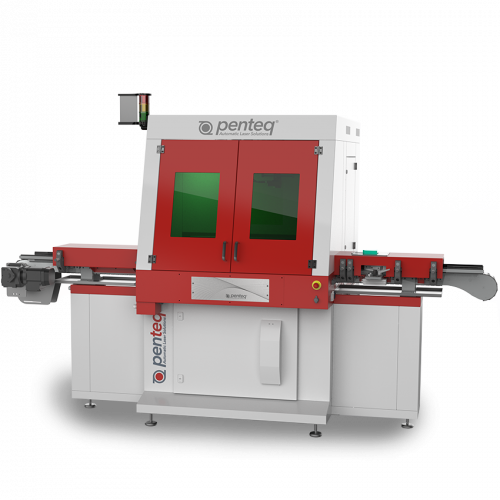

Laser system with pocket wheel

Automatic laser system with optimised material flow

Laser workstation LG300

Spacious work area and double pull-out table for maximum throughput rates

LG300 RT round table laser system

Maximum productivity in large format

Laser workstation LG 500

the top class for XL formats in laser processing

SG200 Weld

Dynamic Precision Welding: Developed for reliable welding of the smallest components with state-of-the-art software and camera technology.

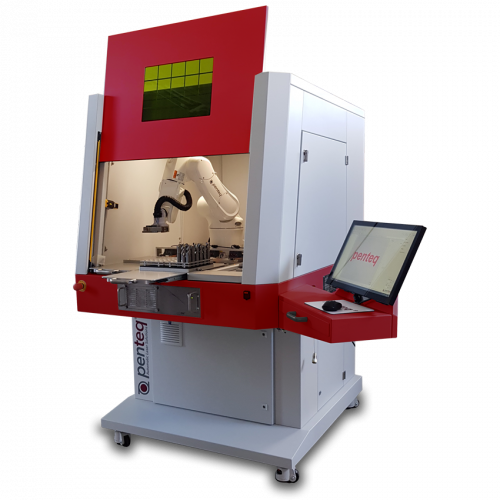

SG 500 RoboLaser

Flexibility through laser robots

Laser system with conveyor belt

Automatic laser system with flexible workpiece carriers

LG500 A Double shutter

Automatic loading system for large workpieces

Laser workstation LG 500 Robo

Fully automatic and flexible with integrated robot

Applications

Stripping

Stripping & stripping of copper wires for the electronics industry

Adhesive surface preparation

Efficiency, sustainability and quality in surface pretreatment

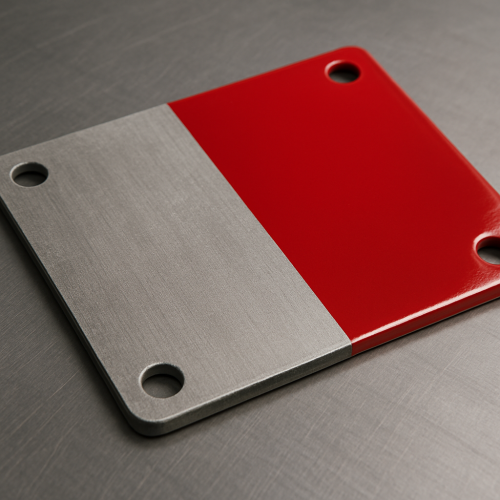

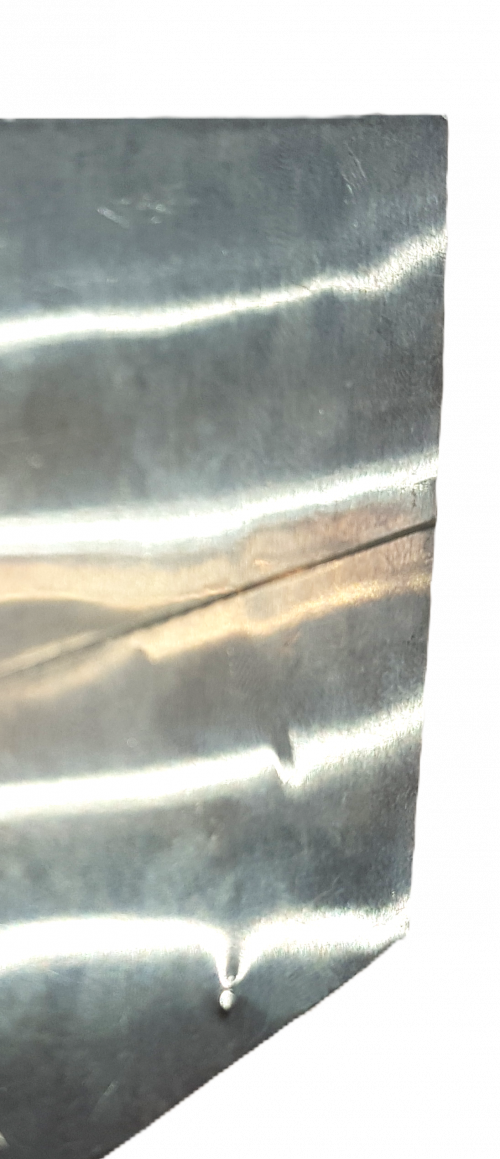

Paint stripping

Entfernen von Lackschichten ohne Chemie oder Strahlmittel: Das Laserentlacken bietet höchste Präzision bei minimalem Materialeinsatz.

Rust removal

Efficient laser cleaning of corroded surfaces

Dynamic Precision Welding

Maximum precision at maximum process speed

Battery cells

Precision for the energy of the future

Spot welding

Precise. Fast. Contactless.

Cutting off plastic sprues

Laser cutting is an innovative, non-contact process for removing sprues from plastic parts directly after injection moulding.

Electromobility - Batteries

Penteq uses lasers to clean, weld and mark battery cells for electromobility in order to optimise battery performance and service life

Industries

Mechanical engineering

We use state-of-the-art laser technology to create precise, durable solutions for demanding plant and mechanical engineering applications

Tool+mould making

Our laser machines enable precise engraving and labelling in tool and mould making, which increases efficiency and adaptation to workpiece geometries

Electronics industry

Penteq laser machines offer precise cutting, welding and marking for the electrical industry, ideal for battery cells and electronic components

Automotive industry

Penteq laser machines enable precise cutting, welding and labelling in the automotive industry, especially for batteries and metal components

Medical technology

Penteq laser machines offer precise, durable markings in medical technology that are corrosion-resistant and suitable for sterilisation

Clocks and Jewelry

Penteq laser machines enable watch and jewellery manufacturers to make precise engravings and markings on metals, ideal for personalised designs

Tool manufacturer

Penteq laser systems enable precise, efficient and cost-saving production of durable tools - innovative and robust

Air+Space

With innovative laser technology, Penteq delivers precise and reliable solutions for the highest demands in the aerospace industry

Maritime industry

Penteq supplies robust laser technology for precise material processing and labelling despite the harshest maritime environments