Signolux® UltraShortPulseLaser

Precision & quality for the highest demands

You can also visit the Signolux UKP on our

The perfect system for exclusive results

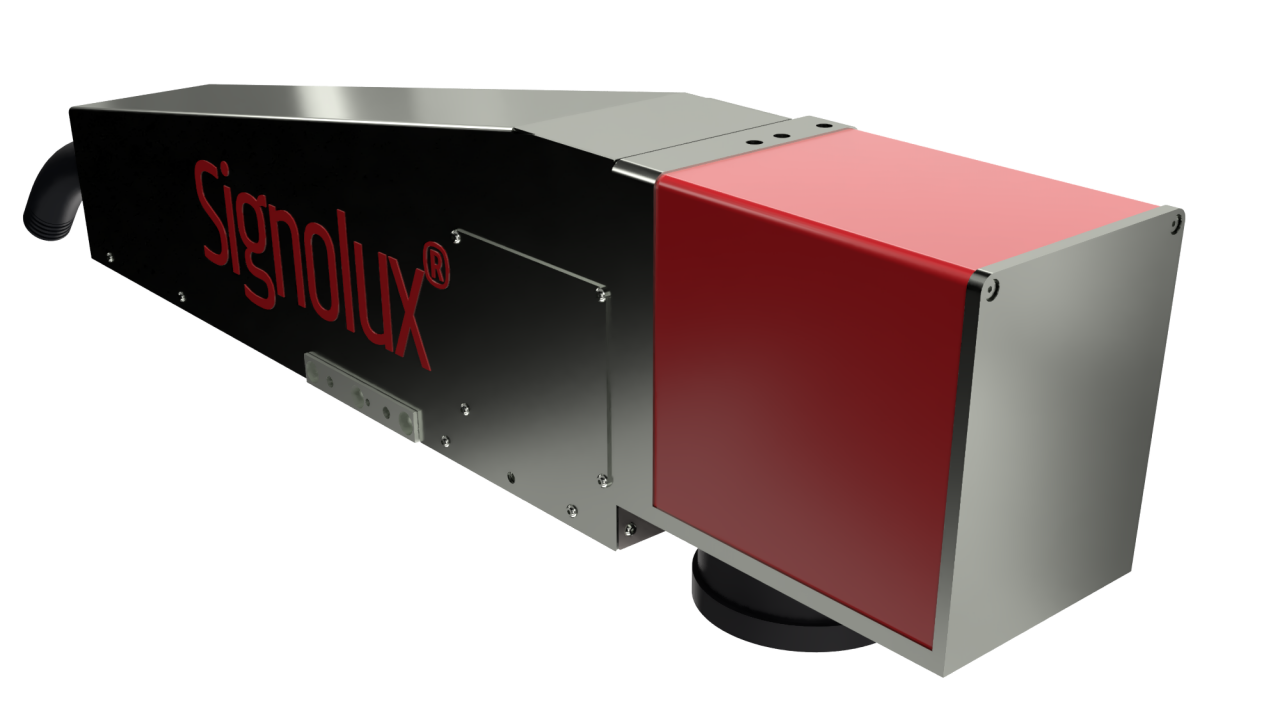

The Signolux® UltraShortPulseLaser is the premium laser system for high-quality labelling and ultra-fine processing of glass, metal or plastic. The innovative UltraShortPulse technology enables precise results with minimal heat influence, making it ideal for applications in medical technology, microstructuring or sensitive cleaning processes.

With the UltraBlackMarking process, the Signolux® creates high-contrast, black markings that are visible from any viewing angle and without compromising corrosion resistance. Thanks to its unique design with a water-cooled rack, the laser remains stable and reliable even under continuous load.

The compact design in 19″ format, combined with the proven Pensoft software, makes the system easy to integrate and intuitive to use.

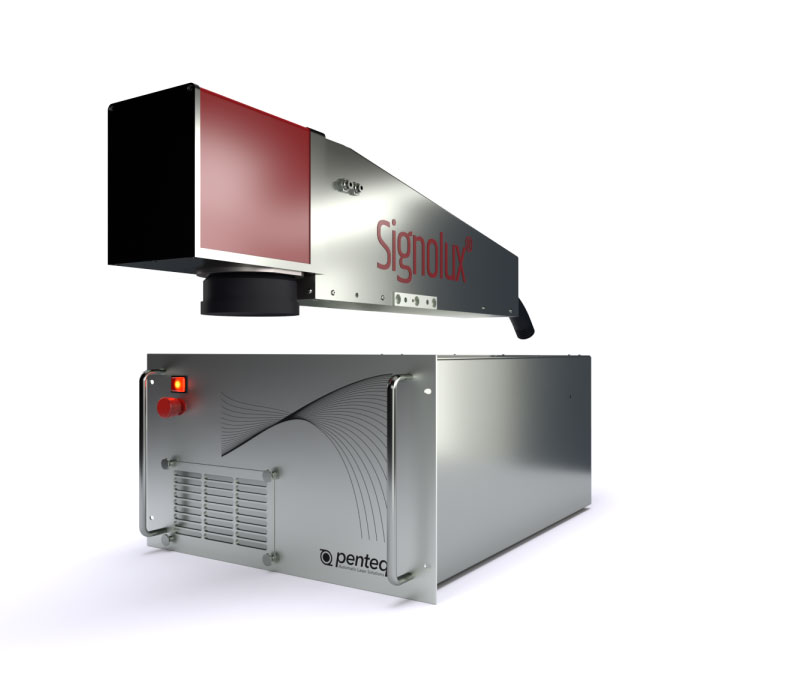

Unique structure

The supply unit, controller and industrial PC of the Signolux® ultra-short pulse laser are compactly integrated in a 19″ format. All heat-generating components are located in the water-cooled rack, which ensures optimum temperature stability.

Precise machining thanks to "cold" process

Thanks to the cold laser process, the processed materials remain undeformed and their properties unaffected - perfect for demanding applications.

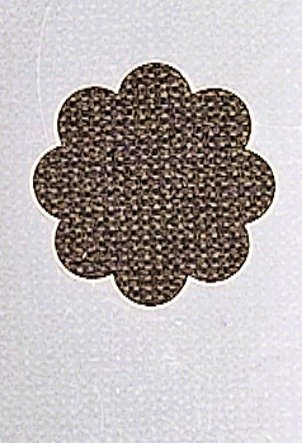

UltraBlackMarking

The process enables deep black, high-contrast markings on stainless steel that also fulfil the highest requirements in medical technology.

User-friendly software

The intuitive Pensoft software makes it easy to create and adapt programmes.

Optional extensions

Expand the Signolux® UltraShortPulseLaser with functions such as 3D processing, positioning laser or laser fume extraction to fulfil even complex requirements.

Signolux® UltraShortPulseLaser - rely on top-class precision

Achieve outstanding results with the Signolux® UltraShortPulseLaser. Whether filigree structures, high-contrast labelling or demanding applications - this system opens up completely new possibilities for you. Contact us and let us advise you individually.

| Power (watts) | 50 |

| Laser type | Ultra-short pulse laser (picoseconds) |

| Wavelengths | 1030 nm + / - 10 nm |

| Pulse rate | 60 - 1000 kHz (in steps) |

| Standard field of work | 105 x 105 mm (focus distance approx. 194mm)Others on request |

| Weight: Laser / supply unit | approx. 20 kg / approx. 30 kg |

| Fibre length | 2,5 m |

| Cooling | Water-cooled |

| Supply voltage | 230 V 50 Hz |

| Power consumption | approx. 900 W |

| Electrical interfaces | 2 x USB, 1 x Ethernet |

| Software interfaces | TCP/IP (standard), Profinet, OPC-UA, Ethercat. Others possible after clarification |

| Ambient temperature | +15 to +35°C |

| Rel. humidity | 10% to 80% (non-condensing) |

| IP protection class | IP 54 |

| Determined service life | Typically over 50,000 hours |

| Software | PenSoft Editor |

| Input | Full HD monitor with mouse & keyboard |

| Operating system | Windows 11 |

| Laser class | Laser class 4 |

Matching products

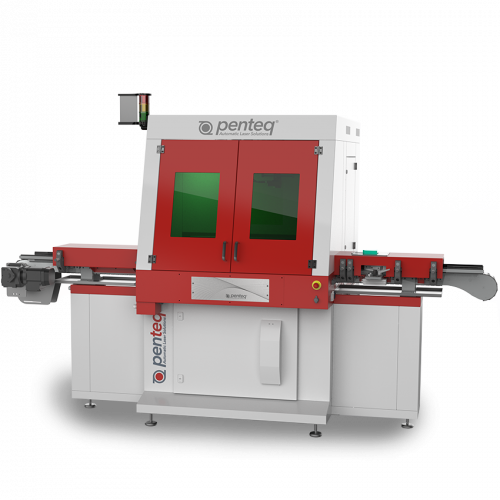

Rotary transfer laser system

Automatic with flexible workpiece holders

Laser system with pocket wheel

Automatic laser system with optimised material flow

Laser workstation LG300

Spacious work area and double pull-out table for maximum throughput rates

LG300 RT round table laser system

Maximum productivity in large format

Laser workstation LG 500

the top class for XL formats in laser processing

Laser system with conveyor belt

Automatic laser system with flexible workpiece carriers

LG500 A Double shutter

Automatic loading system for large workpieces

Applications

Cutting tools

Flexible and durable laser labelling

Wristwatches

Finest engravings with ultra-short pulse technology

Glass + ceramics

High-quality labelling, logos, fonts and codes

Medical devices UDI

Ultra Black Marking - UDI-compliant and permanent labelling

Technical films

Precision at the speed of light - laser cutting of foils with Galvo technology

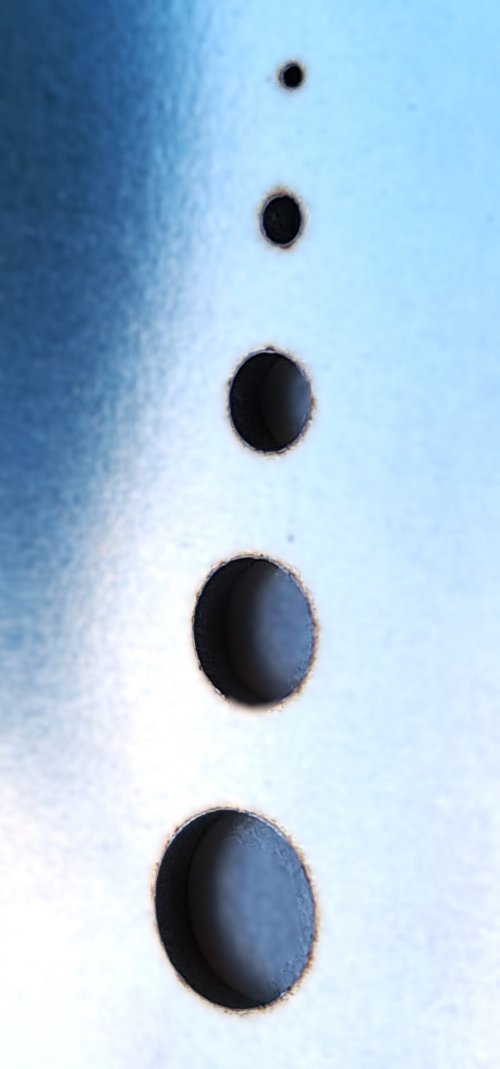

Perforating and punching

Precision laser perforation for demanding materials.

Electronics housing

Customised, precise and permanently legible laser markings for the highest demands in the electronics industry

White goods

Laser labelling in the visible area of a microwave, cooker, washing machine or coffee machine places the highest demands on quality.

Industries

Mechanical engineering

We use state-of-the-art laser technology to create precise, durable solutions for demanding plant and mechanical engineering applications

Tool+mould making

Our laser machines enable precise engraving and labelling in tool and mould making, which increases efficiency and adaptation to workpiece geometries

Electronics industry

Penteq laser machines offer precise cutting, welding and marking for the electrical industry, ideal for battery cells and electronic components

Automotive industry

Penteq laser machines enable precise cutting, welding and labelling in the automotive industry, especially for batteries and metal components

Plastics industry

Penteq laser machines provide the plastics industry with precise cutting and marking, enabling clean cuts and permanent labelling to increase production efficiency

Glass manufacturer

Penteq laser machines enable glass manufacturers to produce precise engravings and permanent markings, ideal for logos and QR codes on glass surfaces

Medical technology

Penteq laser machines offer precise, durable markings in medical technology that are corrosion-resistant and suitable for sterilisation

Clocks and Jewelry

Penteq laser machines enable watch and jewellery manufacturers to make precise engravings and markings on metals, ideal for personalised designs

Tool manufacturer

Penteq laser systems enable precise, efficient and cost-saving production of durable tools - innovative and robust

Air+Space

With innovative laser technology, Penteq delivers precise and reliable solutions for the highest demands in the aerospace industry

Maritime industry

Penteq supplies robust laser technology for precise material processing and labelling despite the harshest maritime environments

Packaging industry

Our laser systems integrate seamlessly into high-speed lines and ensure maximum efficiency in packaging labelling