Type plates

High-precision and durable rating plates thanks to laser marking

Laser type plates

Customised, precise and permanently legible laser markings for the highest demands in industry and production.

Penteq offers you the widest range of laser systems for type plates on the market, suitable for every application, from one-off production to large-scale production.

Variety & quality - razor-sharp laser labelling for your nameplates

The advantages of the laser lie in the wide range of applications and the outstanding labelling quality.

With laser systems from Penteq, you benefit from excellent labelling quality on almost any material. Our lasers are perfect for labelling nameplates clearly and permanently. Various processes are available to you, such as engraving, the removal of anodised and coloured layers or the precise removal of the surface.

In addition to classic black nameplates made of anodised aluminium, you can easily mark stainless steel, plastics, brass or other materials such as painted surfaces. Regardless of whether you need small quantities or automated mass production - with Penteq you get the right solution for every requirement.

Non-contact labelling - highly precise and gentle on materials

Penteq's laser systems mark materials completely contact-free, so that even sensitive surfaces remain undamaged. Because the laser does not physically touch the workpiece, there is no risk of scratches or damage.

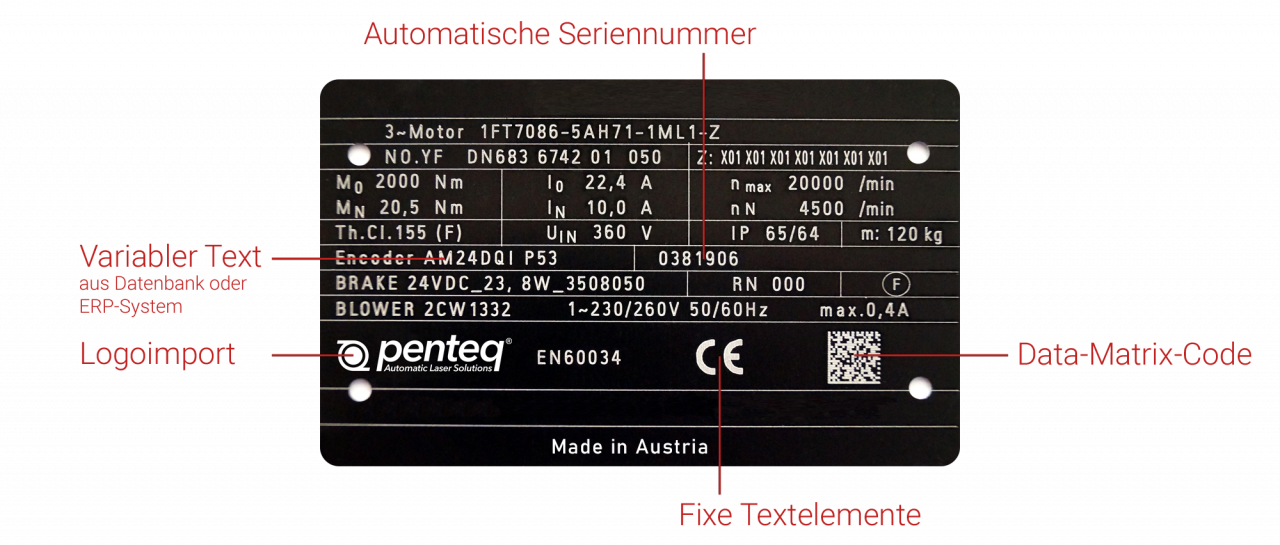

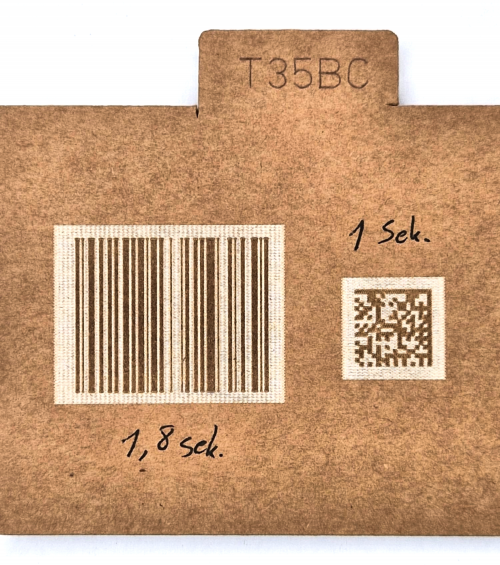

Thanks to the precise and pinpoint laser guidance, you always get razor-sharp markings in permanently legible quality - the laser beam can produce markings with small character sizes and high-resolution graphics, making it ideal for applications that require intricate markings. This allows you to apply serial numbers, codes or logos reliably and permanently legibly to almost any material

Unique & versatile - customised laser markings according to your requirements

Penteq's laser systems offer a wide range of customisation options, allowing you to apply individual markings exactly as you want them. The laser beam can be used to create not only different colours and shades, but also highly visible or discreet and concealed markings.

Laser labelling is a versatile, reliable technology that allows you to mark nameplates permanently, precisely and gently. Use it for labelling simple systems for small quantities or choose semi-automatic and fully automatic systems for the production of large and very large quantities. Our solutions can be flexibly adapted to any requirement. You always benefit from high labelling quality, a wide range of design options and reliable, efficient production - from individual items to industrial mass production.

Your benefits from laser marking at a glance

Wide range of applications

- Suitable for almost all materials (e.g. aluminium, stainless steel, brass, plastic)

- Different processes available: engraving, annealing marking or colour layer removal

Maximum flexibility

- No minimum quantities per label variant

- Customised production directly in the production line ("just-in-time")

- Simple customisation of content (serial numbers, codes, logos)

Forgery-proof and traceable

- Permanently readable DataMatrix and barcodes

- Protection against tampering thanks to tamper-proof labelling

Durable, robust labelling

- High resistance to heat, chemicals and abrasion

- Safe and flexible installation on a wide variety of surfaces

Efficient and economical

- No surplus due to demand-orientated production

- Reduced procurement and administration costs

- No minimum quantities required

How many type plates would you like to label?

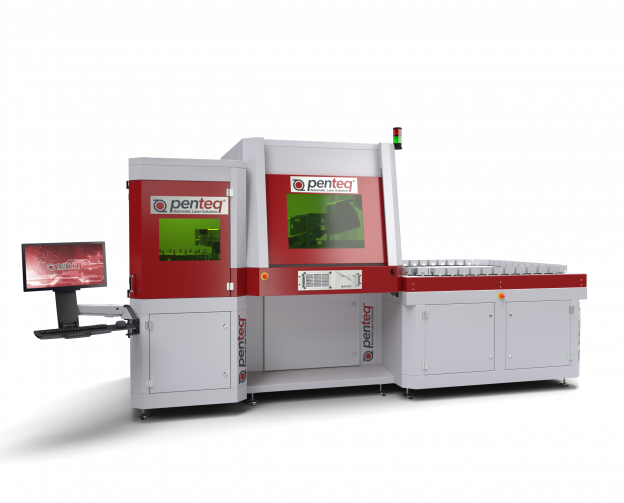

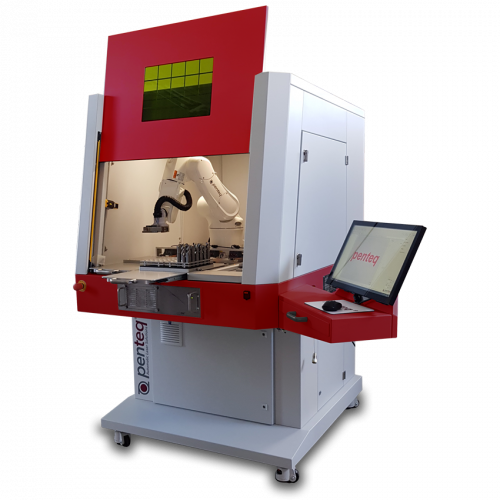

Industrial mass production with high autonomy

LG300 PL SB50

Suitable products

FM Cardmaker

From manual machine to automatic labelling machine. With the Cardmaker function module, nameplates can also be automatically labelled with consecutive numbers or variable data

Laser workstation LG 200

Modularity as a pioneering concept

PenSoft Control

Easy-to-use interface for laser applications

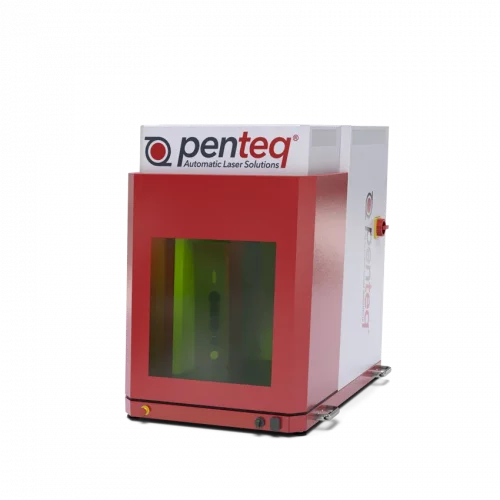

Smartlaser LG20

The intuitive system for professional results

Desktop Laser LG50

Simple, compact and reliable

Desktop Laser LG100

Premium table system in industrial laser technology

Desktop Laser LG150

The all-rounder in industrial laser technology

Rotary table laser LG200 RT

For maximum production speed

Laser workstation LG300

Spacious work area and double pull-out table for maximum throughput rates

LG300 RT round table laser system

Maximum productivity in large format

Laser workstation LG 500

the top class for XL formats in laser processing

SG200 Weld

Dynamic Precision Welding: Developed for reliable welding of the smallest components with state-of-the-art software and camera technology.

OEM fibreline

Ready-to-install laser for numerous applications

Type plate laser machine LG200 PL SB10

for all types of signs

Type plate laser machine LG300 PL SB50

For all types of signs

Type plate laser machine LG200 PL SB50

For all types of signs

LG500 A Double shutter

Automatic loading system for large workpieces

LG200 RT with vibratory feeder

based on LG200 RT rotary table laser system for automatic labelling of bulk goods

Laser workstation LG 500 Robo

Fully automatic and flexible with integrated robot

Rotary transfer laser system

Automatic with flexible workpiece holders

Further applications

White goods

Laser labelling in the visible area of a microwave, cooker, washing machine or coffee machine places the highest demands on quality.

Cutting tools

Flexible and durable laser labelling

Tool + mould making

Industrial laser marking for tools and moulds

Glass + ceramics

High-quality labelling, logos, fonts and codes

Medical devices UDI

Ultra Black Marking - UDI-compliant and permanent labelling

Electronics housing

Customised, precise and permanently legible laser markings for the highest demands in the electronics industry

Packaging

Perfect for recycling: direct labelling on cardboard packaging.

Wristwatches

Finest engravings with ultra-short pulse technology

Industries

Mechanical engineering

We use state-of-the-art laser technology to create precise, durable solutions for demanding plant and mechanical engineering applications

Tool+mould making

Our laser machines enable precise engraving and labelling in tool and mould making, which increases efficiency and adaptation to workpiece geometries

Electronics industry

Penteq laser machines offer precise cutting, welding and marking for the electrical industry, ideal for battery cells and electronic components

Automotive industry

Penteq laser machines enable precise cutting, welding and labelling in the automotive industry, especially for batteries and metal components

Air+Space

With innovative laser technology, Penteq delivers precise and reliable solutions for the highest demands in the aerospace industry

Packaging industry

Our laser systems integrate seamlessly into high-speed lines and ensure maximum efficiency in packaging labelling

Maritime industry

Penteq supplies robust laser technology for precise material processing and labelling despite the harshest maritime environments