Desktop Laser LG100

Premium table system in industrial laser technology

You can also visit the LG100 desktop laser on our

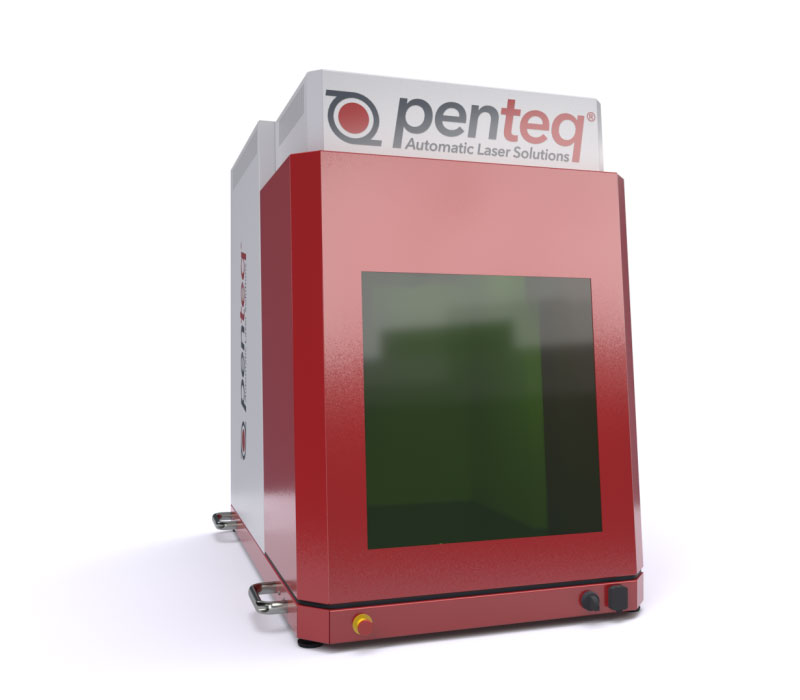

LG 100 DeskTop laser system

Flexibility and precision for industrial applications

The LG 100 Premium DeskTop laser system was developed to meet the highest demands in terms of efficiency, safety and user-friendliness. The compact system combines powerful laser technology with an innovative door concept. The U-shaped automatic door enables particularly convenient access to the processing area, ideal for fast loading and unloading, even where space is limited. Thanks to its automatic opening and closing function, the door not only contributes to process automation, but also protects the operator with a closed system concept. Combined with an intuitive user interface and optional software connection, this system is the ideal solution for precise laser processing in the smallest of spaces - whether in production, in the laboratory or in the development environment.

Discover the possibilities

Simple and reliable technology.

The development of the LG100 DeskTop laser system focussed on covering a wide range of applications while maintaining small dimensions. The design enables loading with heavier workpieces which is only defined by the table. The robust housing and high-quality components ensure exceptional durability and reliable operation in continuous and shift operation. Rely on quality, safety and efficiency - with the latest generation premium desktop laser system.

Robust industrial design

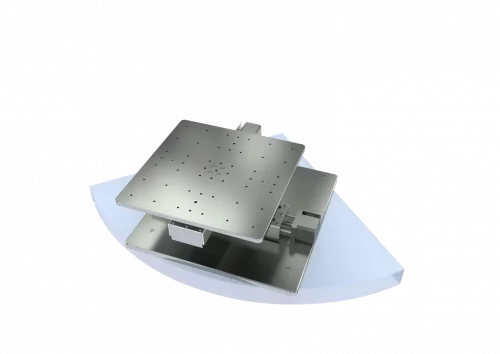

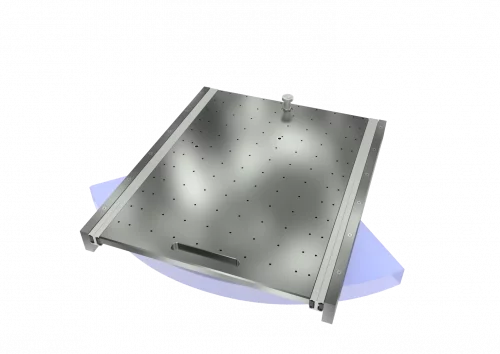

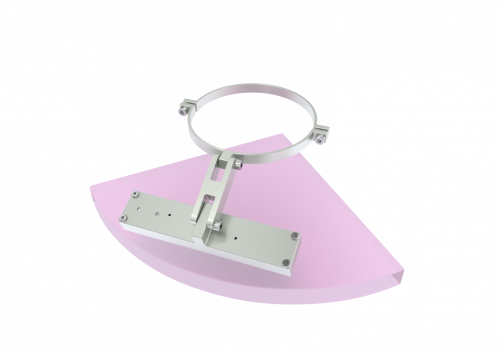

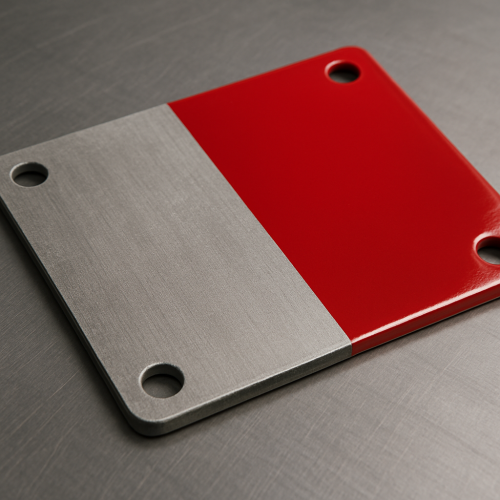

The solid base plate is equipped with a precise hole pattern and hardened bushes, making it ideal for holding fixtures quickly and with repeatable accuracy.

The weight of the workpieces is only limited by the maximum load capacity of the table or base frame.

The protective cabin made of powder-coated steel guarantees stability and durability. Even the basic version of the system contains all the necessary components for smooth operation.

U-shaped automatic door

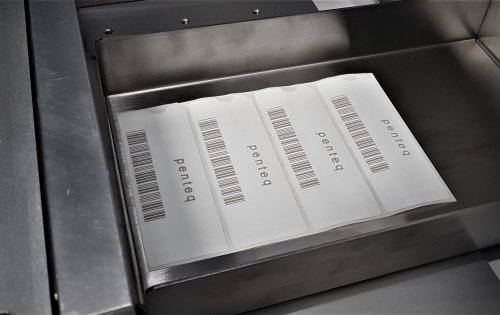

The user-friendly control system enables use without prior knowledge. Labelling content can be called up quickly and easily by scanning barcodes or QR codes. The innovative, U-shaped automatic door opens and closes fully automatically and, thanks to its special geometry, offers particularly generous and barrier-free access to the work area - ideal for easy insertion of workpieces or handling with devices, even in confined spaces.

Large laser protection window

A generously dimensioned laser safety window provides a safe and at the same time optimum view of the machining process, for maximum control without compromising on work safety. The wide-opening door with integrated laser safety window provides optimum access to the work area and enables safe process monitoring during operation.

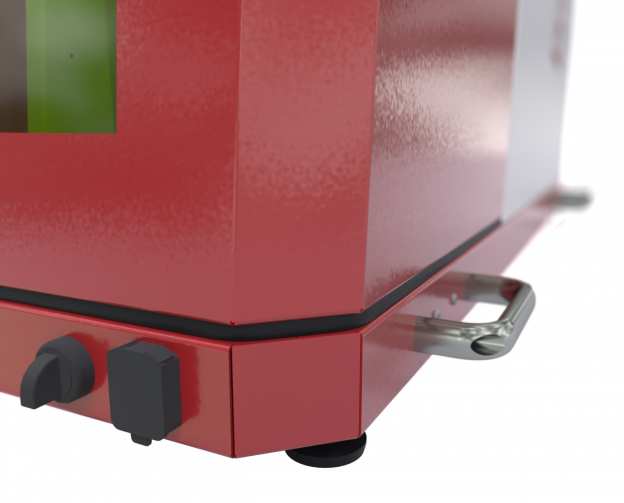

Adjustable machine feet

Adjustable machine feet ensure a secure stand and allow the system to be precisely aligned - even on uneven work surfaces. A stable table is available as an option, which enables ergonomic positioning of the system. This also ensures that all components such as the supply unit and extraction system are neatly stored.

| Workspace | 490 x 285 x 300 mm (WxDxH) |

| Max. Weight of the workpiece per carrier | 50kg |

| Services | 20, 30 and 50 watts |

| Simple field of work | 150 x 150 mm (other sizes on request) |

| Active medium | Ytterbium |

| Dimensions | 600 x 900 x 890 mm (WxDxH) |

| Weight of the system | approx. 150 kg |

| Security | Laser class 1 (with positioning laser LK2) |

- Rotary axis

- PSA (Penteq Smart Adjust)

- Cardmaker

- Table

Software

- Pensoft Control

- Pensoft JobManager

- Penteq App Development

Accessories

- DMC Camera - VisionSystem Verifier

- Pilot laser

- Laser fume extraction

- Foot switch

- Hand scanner for codes

- touch screen

- Bad parts box

- 3-stage status light

- Fiberline F20

- Fiberline F30

- Fiberline F50

The LG100 Premium desktop laser station is equipped with a particularly high-quality, U-shaped automatic door that enables fast, safe and ergonomic loading and unloading of workpieces. The automatic door opening is motorised and is fully integrated into the machine control system. Thanks to the industrial-grade design with stable guide elements, robust drive technology and durable mechanics, the system fulfils the highest requirements for precision and reliability in continuous operation. The U-shaped door geometry allows free access to the entire work area from three sides, thus improving handling, even with larger or bulky components. The automated opening and closing movement significantly reduces manual effort, which not only improves ergonomics but also significantly shortens the cycle time in series production. Compared to manual door solutions, the automatic door saves several seconds per cycle in everyday production. With short processing times, this can mean an increase in productivity of over 40% per shift. At the same time, process reliability is increased as operating errors when opening or closing are ruled out and the safety circuit remains reliably closed at all times. The combination of high-quality components, automated handling and efficient accessibility makes this laser station the ideal solution for demanding labelling processes with high quality and throughput requirements.

Cost-effectiveness comparison: automatic door vs. manual door

| Procedure | Automatic door | Manual door |

| Open door | approx. 1.0 second | approx. 3-5 seconds (depending on the operator) |

| Insert / remove workpiece | Equal | Equal |

| Close door | approx. 1.0-1.5 seconds | approx. 3-5 seconds |

| Total door cycle time | approx. 2-3 seconds | approx. 6-10 seconds |

| Cycle time saving | approx. 3-7 seconds per cycle | - |

Calculation example for 1-shift operation (8 hours, 2,880 seconds productive time at 100% capacity utilisation)

Assumptions: Laser process duration 5 seconds

Workpiece handling (insertion/removal) 4 seconds

Production in cycle operation (i.e. opening, removing, inserting, closing counts per cycle)

| Door | Door time | Total time/cycle | Cycles per hour | Parts per shift (8h) |

| Automatic | 3 sec. | 5 (laser) + 4 (handling) + 3 = 12 sec. | 300 | 2400 parts |

| Manual | 8 sec. | 5 + 4 + 8 = 17 sec. | 211 | 1688 parts |

An automatic door saves a significant amount of time. This saving has a direct impact on the parts output per shift and therefore on profitability. With short processing times per part, the door cycle is a critical bottleneck - this is where automation is particularly worthwhile.

Downloads

Matching products

FM XY table

The automatically movable X/Y table enables the marking field to be enlarged in the X and Y directions

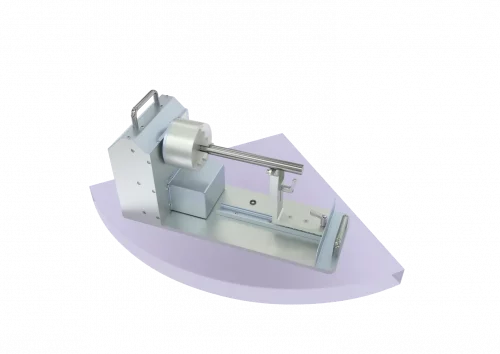

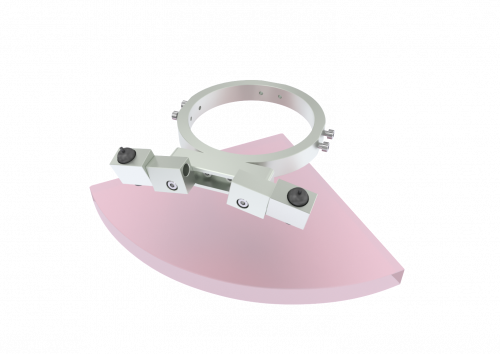

FM Rotary axis

The rotary axis function module (dividing head) is used for segmental labelling of the lateral surface on cylindrical components.

FM Extendable table

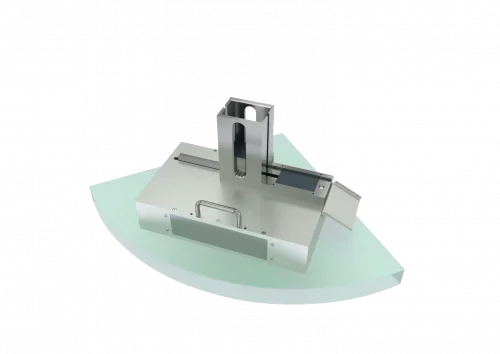

The door can be opened completely and the support table pulled out towards the operator for adjustment and set-up work, as well as for picking up large or heavy parts.

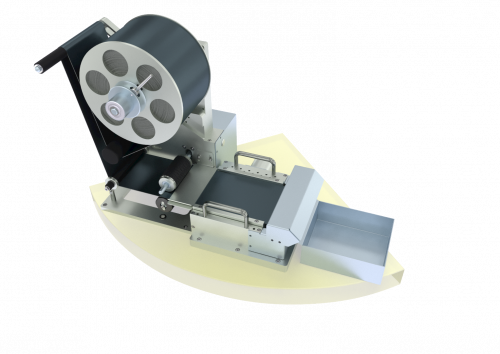

FM Cardmaker

From manual machine to automatic labelling machine. With the Cardmaker function module, nameplates can also be automatically labelled with consecutive numbers or variable data

PenSoft Control

Easy-to-use interface for laser applications

FM Labemaker

Label and cut permanent laser labels in any shape and size with the Labelmaker function module

FM focus finder

Easily detect the component height with the focus finder function module

FM SmartAdjust (PSA)

Use the SmartAdjust function module to position the machining layout on the workpiece

VisionSystem Verifier

Verification of e.g: Data Matrix codes, barcodes, QR codes, etc.

Smoke extraction systems

Reliably extract and filter laser smoke, laser particles and fumes

VisionSystem Check and Confirm

Checking data matrix codes, barcodes, QR codes by reading against them

Signal light

Reliable signalling for maximum visibility and safety

PenSoft Connect IP

Software für die Typenschildproduktion

Schwenkarm

Komfort und Funktionalität in perfekter Harmonie

Hand scanner

Powerful, flexible and reliable

Foot switch

Foot switch for Penteq laser machines

Applications

Name plates

Customised, precise and permanently legible laser markings for the highest demands in industry and production.

Adhesive surface preparation

Efficiency, sustainability and quality in surface pretreatment

Paint stripping

Removing paint without chemicals or blasting media

Cutting tools

Flexible and durable laser labelling

Rust removal

Efficient laser cleaning of corroded surfaces

Wristwatches

Finest engravings with ultra-short pulse technology

Tool + mould making

Industrial laser marking for tools and moulds

Glass + ceramics

High-quality labelling, logos, fonts and codes

Medical devices UDI

Ultra Black Marking - UDI-compliant and permanent labelling

Cutting off plastic sprues

Laser cutting is an innovative, non-contact process for removing sprues from plastic parts directly after injection moulding.

Technical films

Precision at the speed of light - laser cutting of foils with Galvo technology

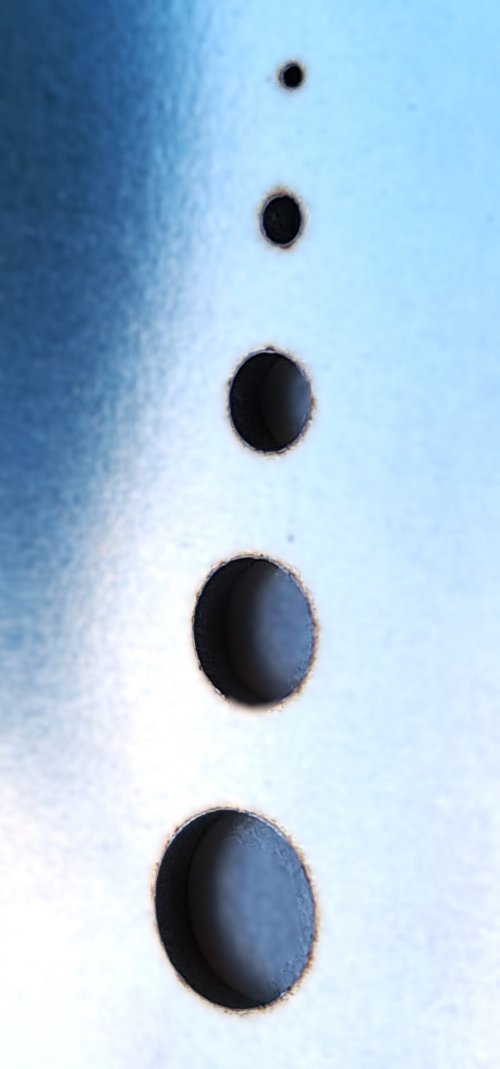

Perforating and punching

Precision laser perforation for demanding materials.

Laser labels - Laser foils

Flexible, tamper-proof and permanent labelling

Electronics housing

Customised, precise and permanently legible laser markings for the highest demands in the electronics industry

White goods

Laser labelling in the visible area of a microwave, cooker, washing machine or coffee machine places the highest demands on quality.

Industries

Mechanical engineering

We use state-of-the-art laser technology to create precise, durable solutions for demanding plant and mechanical engineering applications

Tool+mould making

Our laser machines enable precise engraving and labelling in tool and mould making, which increases efficiency and adaptation to workpiece geometries

Electronics industry

Penteq laser machines offer precise cutting, welding and marking for the electrical industry, ideal for battery cells and electronic components

Automotive industry

Penteq laser machines enable precise cutting, welding and labelling in the automotive industry, especially for batteries and metal components

Plastics industry

Penteq laser machines provide the plastics industry with precise cutting and marking, enabling clean cuts and permanent labelling to increase production efficiency

Glass manufacturer

Penteq laser machines enable glass manufacturers to produce precise engravings and permanent markings, ideal for logos and QR codes on glass surfaces

Medical technology

Penteq laser machines offer precise, durable markings in medical technology that are corrosion-resistant and suitable for sterilisation

Clocks and Jewelry

Penteq laser machines enable watch and jewellery manufacturers to make precise engravings and markings on metals, ideal for personalised designs

Tool manufacturer

Penteq laser systems enable precise, efficient and cost-saving production of durable tools - innovative and robust

Air+Space

With innovative laser technology, Penteq delivers precise and reliable solutions for the highest demands in the aerospace industry

Maritime industry

Penteq supplies robust laser technology for precise material processing and labelling despite the harshest maritime environments

Packaging industry

Our laser systems integrate seamlessly into high-speed lines and ensure maximum efficiency in packaging labelling